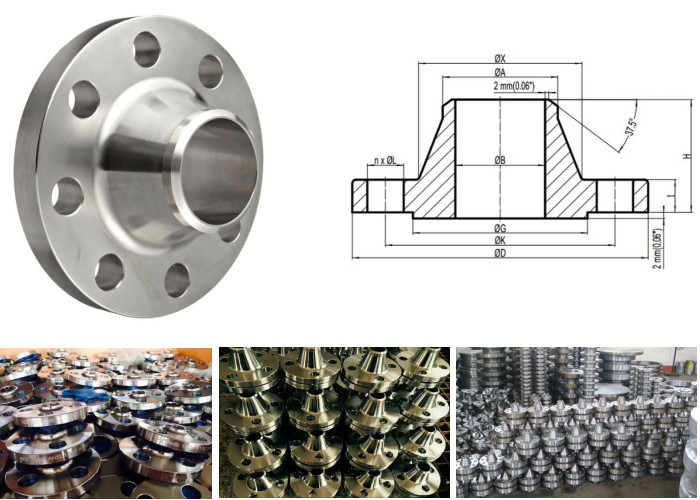

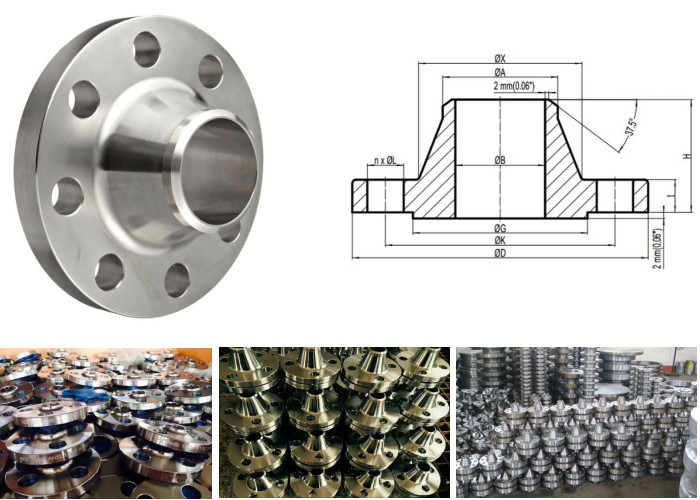

Forged DN125A - 250A Weld Neck Pipe Flanges Galvanizing For Oil

Pipe Connection Size2'-24'

1.Carbon Steel

Carbon Steel :A105,CT20,CT25,P245GH Low Temperature

Carbon Steel: ASTM SA350 LF2

High Strength Steel: ASTM SA694 F42/46/52/56/60/65/70

AISI classification

Carbon steel is broken down into four classes based on carbon

content:

Low-carbon steel

0.05 to 0.30% carbon (plain carbon steel) content.

Medium-carbon steel

Approximately 0.3–0.6% carbon content.Balances ductility and

strength and has good wear

resistance; used for large parts, forging and automotive

components.

High-carbon steel

Approximately 0.60 to 1.00% carbon content.Very strong, used for

springs, edged tools, and high-

strength wires.

2.ASTM B 16.5

The B16.5 Standard defines the following:

(1) Dimensions

(2) Tolerances

(3) Materials

(4) Markings

(5) Pressure/Temperature Ratings

(6) Pressure Testing

| ASME B16.5 |

| Blind | Lap Joint | Slip On | Socket Weld | Threaded | Weld Neck |

| Flange Dimensions | Flange Dimensions | Flange Dimensions | Flange Dimensions | Flange Dimensions | Flange Dimensions |

| Class 150 | Class 150 | Class 150 | Class 150 | Class 150 | Class 150 |

| Class 300 | Class 300 | Class 300 | Class 300 | Class 300 | Class 300 |

| Class 400 | Class 400 | Class 400 | Class 600 | Class 400 | Class 400 |

| Class 600 | Class 600 | Class 600 | Class 1500 | Class 600 | Class 600 |

| Class 900 | Class 900 | Class 900 | | Class 900 | Class 900 |

| Class 1500 | Class 1500 | Class 1500 | | Class 1500 | Class 1500 |

| Class 2500 | Class 2500 | Class 2500 | | Class 2500 | Class 2500 |

3.Product catalogue

| Specification | |

| Product | Flange |

| Size | 1/2"-72" |

| Type | Weld Neck, Slip-On, Blind, Socket Weld, Lap Joint,Spectacle

Blind,Etc |

| Standard | ANSI, ASME ,MSS, API, DIN, JIS, BS. AWWA,GOST,EN and GB |

| Class | ANSI 150LBS-2500LBS, |

| DIN PN6-PN160 |

| BS PN0.25-PN25 PN2.0-PN42.0 |

| JIS 5K-30K |

| Materials | Carbon Steel :A105,CT20,CT25,P245GH |

| Low Temperature Carbon Steel: ASTM SA350 LF2 |

| High Strength Steel: ASTM SA694 F42/46/52/56/60/65/70 |

| Stainless Steel | ASTM A182 F304/304L/316/316L |

| Alloy Steel | ASTM A182 F1/F5/F9/F11/F22/F91/Etc. |

| Duplex stainless steel | ASTM A182 F51/F53/F55/F60 |

| Nicke alloys | Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800 |

| Cu-Ni | 90/10,70/30 |

| Process | Free forging, plate cutting. |

| Printing | Carbon steel and alloy steel with yellow print, black print, oil or

zinc. |

| Packing | Plywood case |

| Delivery | Usually within one month after receiving the formal order . |

| Inspection | Factory in-house or Third Party inspection available upon requests. |

4.Product display

5.ASME standards (U.S.)

Pipe flanges that are made to standards called out by ASME B16.5 or

ASME B16.47, and MSS SP-44.

They are typically made from forged materials and have machined

surfaces. ASME B16.5 refers to

nominal pipe sizes (NPS) from ½" to 24". B16.47 covers NPSs from

26" to 60". Each specification

further delineates flanges into pressure classes: 150, 300, 400,

600, 900, 1500 and 2500 for B16.5,

and B16.47 delineates its flanges into pressure classes 75, 150,

300, 400, 600, 900. However these

classes do not correspond to maximum pressures in psi. Instead, the

maximum pressure depends on

the material of the flange and the temperature. For example, the

maximum pressure for a Class 150

flange is 285 psi, and for a Class 300 Flange it is 740 psi (both

are for ASTM A105 Carbon Steel and

temperatures below 100F).

The gasket type and bolt type are generally specified by the

standard(s); however, sometimes the

standards refer to the ASME Boiler and Pressure Vessel Code

(B&PVC) for details (see ASME Code

Section VIII Division 1 – Appendix 2). These flanges are recognized

by ASME Pipe Codes such as

ASME B31.1 Power Piping, and ASME B31.3 Process Piping.

Materials for flanges are usually under ASME designation: SA-105

(Specification for Carbon Steel

Forgings for Piping Applications), SA-266 (Specification for Carbon

Steel Forgings for Pressure Vessel

Components), or SA-182 (Specification for Forged or Rolled

Alloy-Steel Pipe Flanges, Forged Fittings,

and Valves and Parts for High-Temperature Service). In addition,

there are many "industry standard"

flanges that in some circumstance may be used on ASME work.

The product range includes SORF, SOFF, BLRF, BLFF, WNRF (XS, XXS,

STD & Schedule 20, 40, 80),

WNFF (XS, XXS, STD & Schedule 20, 40, 80), SWRF (XS & STD), SWFF

(XS & STD), Threaded RF,

Threaded FF & LJ, with sizes from 1/2" to 16". The bolting material

used for flange connection is stud

bolts mated with two nut (washer when required). In Petrochemical

industries, ASTM A193 B7 STUD

& ASTM A193 B16 Stud Bolts are used as these have high tensile

strength.

6.Galvanizing

Galvanizing protects the underlying iron or steel in the following

main ways:

The zinc coating, when intact, prevents corrosive substances from

reaching the underlying steel or iron.

The zinc protects iron by corroding first. For better results,

application of chromates over zinc is also

seen as an industrial trend.

In the event the underlying metal becomes exposed, protection can

continue as long as there is zinc

close enough to be electrically coupled. After all of the zinc in

the immediate area is consumed,

localized corrosion of the base metal can occur.

Why Choose Us

1.One-Stop Service,One Single Source.

2.No MOQ.

3.Best quality,competitive price

4.Fast Reply.

5.On-Time Delivery

6.Professional sales and technical team .

FAQ

Q1: Are you a factory or a trade company?

A1: We are a professional manufacturer for designing and producing

of Large-size products.(View Mor)

Q2: Do you make customized products or finished parts?

A2: All parts are custom made only, and in stock, we can produce

based on your drawings.

Q3: Will my drawing be e after you get it?

A3: Yes, we will not release your design to third party unless with

your permission.

Q4: What is the MOQ?

A4: Small order is acceptable, but the more, the cheaper.

Q5: How about the samples?

A5: We are happy to make prototype part or sample for clients to

ensure quality standard, but it’s charged according to your

drawing.